Quality Control System Overview

Comprehensive Testing at Every Stage

At iSky Motor, our quality management system covers every stage — from raw material inspection to final product validation.

Through multi-stage inspections, precision testing equipment, and traceable documentation, we catch potential defects early, minimize waste, and ensure 99.8% production accuracy across all batches.

This rigorous process ensures every motor meets exact specifications with full regulatory and warranty compliance — giving you confidence that every unit performs reliably in the field.

Work with our QA engineers to validate your next motor project.

Talk to Our QA TeamIncoming Components Inspection

Ensuring Compliance with RoHS, CE, and International Quality Standards

All materials used in our motors meet RoHS, CE, and relevant environmental safety requirements. We work only with qualified suppliers whose materials can pass strict international compliance checks.

Every incoming batch is inspected following nationally recognized certification standards, ensuring consistency, safety, and reliability before materials enter production. This disciplined approach allows us to maintain stable performance and long-term durability across every motor we deliver.

Need proof of material integrity for your project?

Get Material Compliance ReportsProduction Process Control

Stable Quality Through Skilled Assembly & Real-Time Oversight

Gearbox-motor assembly involves many precision operations that benefit from experienced hands rather than full automation. To keep quality consistent, our process relies on continuous real-time oversight—where trained technicians and quality engineers monitor each stage and immediately correct anything outside specification.

Every unit then completes a full functional verification before it is approved for shipment, ensuring predictable performance and reliability across all delivered motors.

Confidence built on controlled processes and verified performance.

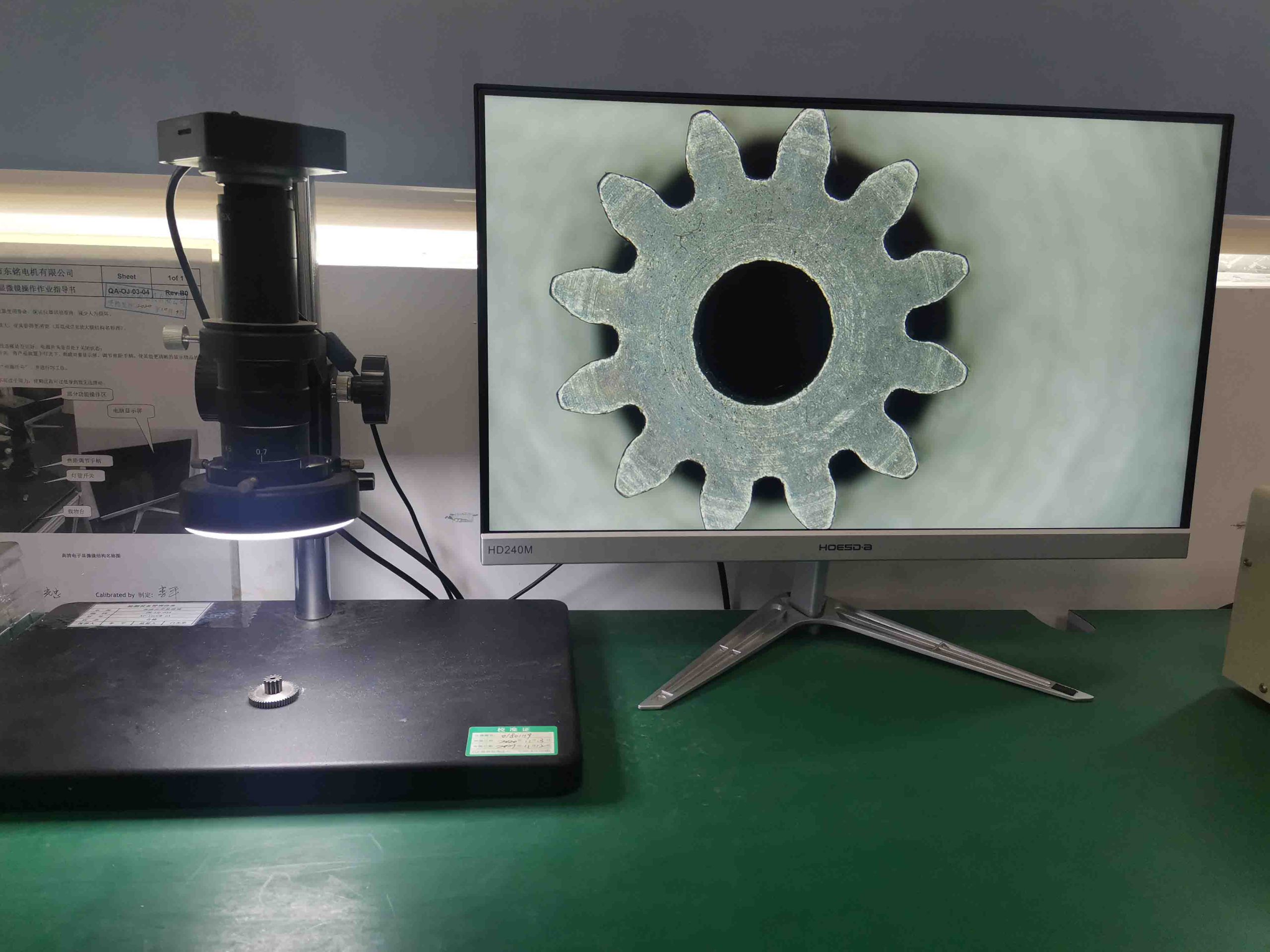

Request Process Verification ReportKey Testing Equipment Showcase

State-of-the-Art Measurement Technology

Want to see our testing capabilities?

Schedule Lab TourCustomer Trust & Application Cases

Proven Reliability Across Global Industries

Smart Curtain

Engineered for smooth and quiet movement, our gear motors deliver high torque with a stable 45–50 dB noise level to ensure reliable curtain operation. Their durable construction provides long-lasting performance with minimal maintenance for residential and commercial systems.

Laundry Dosing System

Designed for precise detergent dispensing, our micro DC motors offer stable and long-lasting output across various dosing applications. Their controlled movement and robust build ensure accurate dosing each cycle while keeping maintenance needs low in continuous use.

Fish Feeder Machine

Built for consistent feed delivery, our sealed-gear DC motors perform reliably in both indoor and outdoor environments. Their stable torque and long service life support continuous operation even under humidity, splashes, and varying weather conditions.

Coffee Machine

Engineered for high-load operation, our compact planetary motors deliver strong torque, quiet performance, and long-term stability for smooth dispensing cycles. Their durable construction ensures reliable output and extended lifespan in demanding coffee machine environments.

Join global brands achieving higher reliability and zero-defect performance with iSky Motor.

Start Your Success StoryWork With iSky Motor

Tell us about your project – we'll get back to you within 24 hours.

Why Choose iSky Motor?

Partner with a trusted DC motor manufacturer combining engineering expertise, flexible customization, and reliable quality.

Whether you need a standard model or a tailor-made motion solution, our team is ready to support your project from concept to production.

- A professional engineer team for design and testing

- Customized motor and gearbox solutions

- Direct factory communication, quick feedback

- International shipping experience

- Flexible MOQ and prototyping options

- Proven experience with European & American clients

- Certified quality management and on-time delivery