SK-LS37-555

- Strong gears & Low noise

- High torque & Long life time

- Application:Dosing system, BBQ, Chicken coop,Touchless towel dispenser,Opener, Smart toilet cover,etc.

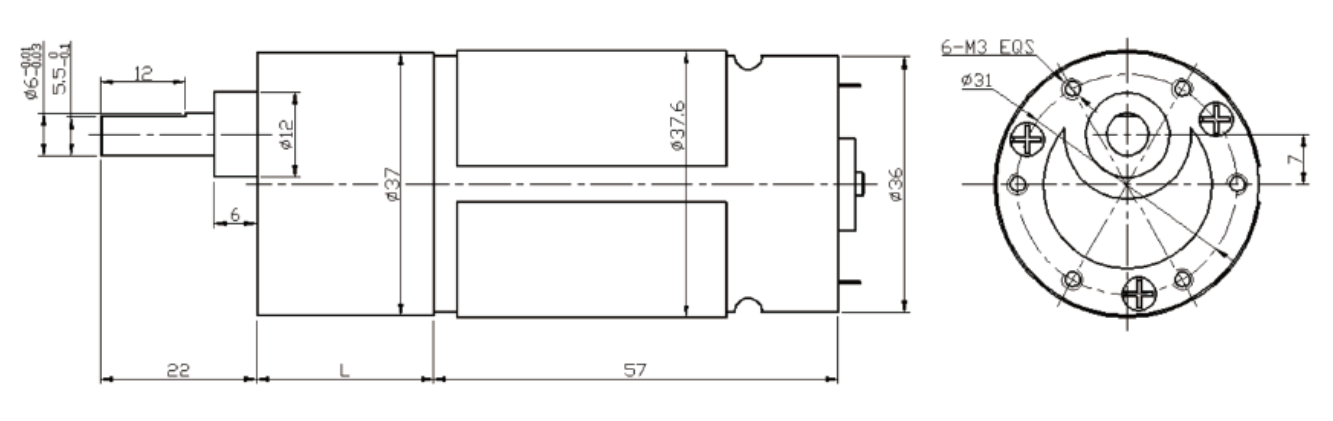

Diameter

37 mm

Voltage

12-24V DC

Speed

1-660 r/min

Torque

0.1-50 kg.cm

Noise Level

≤55 dB

Life time

customizable

Dimensions

All dimensions are in (mm) unless otherwise noted. Drawings are for reference only—please contact us to confirm exact specifications.

Parameters

| Gearbox Stages | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|

| Gear Ratio | 6.8 | 20 | 41 | 107 | 311 | 1243 |

| 10 | 30 | 90 | 122 | 414 | 1657 | |

| / | / | / | 184 | 552 | 2430 | |

| / | / | / | 270 | 810 | / | |

| Gearbox Length L(mm) | 19 | 22.5 | 25 | 27.5 | 30 | 31.5 |

Note: Performance curves show speed-torque characteristics at rated voltage. Custom performance specifications available upon request for specific applications.

Performance Data

| Gearbox Motor Model | Voltage (V) | No Load | Max Efficiency Load | |||

|---|---|---|---|---|---|---|

| Current (A) | Speed (r/min) | Current (A) | Speed (r/min) | Torque (kg.cm) | ||

| SK-LS37-555-24662 | 24 | ≤0.15 | 662 | ≤0.3 | 529 | 1.2 |

| SK-LS37-555-24225 | 24 | ≤0.15 | 225 | ≤0.3 | 180 | 3.2 |

| SK-LS37-555-2450 | 24 | ≤0.15 | 50 | ≤0.3 | 40 | 12.8 |

| SK-LS37-555-2424 | 24 | ≤0.15 | 24 | ≤0.3 | 19.6 | 23.5 |

| SK-LS37-555-2414 | 24 | ≤0.15 | 14 | ≤0.3 | 11.6 | 36.3 |

| SK-LS37-555-246.0 | 24 | ≤0.15 | 6 | ≤0.3 | 4.4 | 50* |

| SK-LS37-555-244.0 | 24 | ≤0.15 | 4 | ≤0.3 | 2.9 | 50* |

| SK-LS37-555-242.0 | 24 | ≤0.15 | 2 | ≤0.3 | 1.5 | 50* |

Remarks:

1. The Performance of gear motor are for reference only. We can customize per your own unique requests.

2. Most of our Customization service are no need extra or new toolings.

3. This gear motor could be matched with Hall sensor encoder.

4. Output shaft could be customized per your drawings.

1. The Performance of gear motor are for reference only. We can customize per your own unique requests.

2. Most of our Customization service are no need extra or new toolings.

3. This gear motor could be matched with Hall sensor encoder.

4. Output shaft could be customized per your drawings.

Frequently Asked Questions

Quick Answers to Common Engineering Questions

What types of DC geared motors do you manufacture?

We manufacture miniature DC geared motors, including planetary, spur, worm, and flat gearbox motors, as well as brushless DC (BLDC) motors with optional Hall sensor and encoder solutions.

Can you customize motors for specific applications?

Yes. We provide customized motor solutions according to your required voltage, torque, speed, dimensions, shaft design, and connector type. Our engineering team helps you achieve the best balance of performance and cost.

What industries and applications do your motors serve?

Our motors are widely used across five main application areas:

Home appliances: electric curtains, coffee machines, BBQ grills, cleaning devices

Commercial equipment: dosing systems, sanitary and medical equipment, firefighting devices, educational robots

Livestock & aquaculture: horse feeder machines, fish feeders, shrimp feeders, bird feeders

Security locks: smart padlocks, safes, access control systems

Valves & meters: flow control valves, measuring instruments, and smart monitoring systems

Home appliances: electric curtains, coffee machines, BBQ grills, cleaning devices

Commercial equipment: dosing systems, sanitary and medical equipment, firefighting devices, educational robots

Livestock & aquaculture: horse feeder machines, fish feeders, shrimp feeders, bird feeders

Security locks: smart padlocks, safes, access control systems

Valves & meters: flow control valves, measuring instruments, and smart monitoring systems

What quality certifications do your products have?

We operate under ISO9001 quality management and comply with RoHS and CE standards. Each motor is 100% tested for torque, speed, and noise before shipment.

Do you support prototype or small-volume orders?

Yes. We welcome prototype and testing orders for product development and validation before mass production.

How long is your typical lead time?

For samples, it usually takes 7–15 days; for mass production, around 25–35 days depending on order quantity and customization complexity.

What are your shipping options and trade terms?

We export to Europe, North America, and South America, and can arrange EXW, FOB, CIF, or DDP shipping terms by air, sea, or express depending on your schedule and budget.

Have a specific technical question not covered here?

Ask Our EngineersWork With iSky Motor

Tell us about your project – we'll get back to you within 24 hours.

Why Choose iSky Motor?

Partner with a trusted DC motor manufacturer combining engineering expertise, flexible customization, and reliable quality.

Whether you need a standard model or a tailor-made motion solution, our team is ready to support your project from concept to production.

- 100+ professional engineers for design and testing

- Customized motor and gearbox solutions

- Direct factory communication, quick feedback

- International shipping experience

- Flexible MOQ and prototyping options

- Proven experience with European & American clients

- Certified quality management and on-time delivery