European Smart Lock Manufacturer Challenge

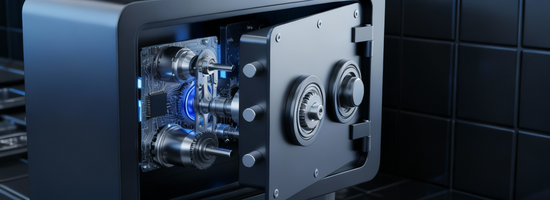

A leading European smart lock manufacturer approached us with a critical challenge: their existing motor solution was too noisy and consumed excessive power, resulting in customer complaints and shortened battery life.

Reduce noise levels by 60% while maintaining torque output and extending battery life by 40% in a space-constrained design.

Our engineering team developed a custom worm gear motor with specialized noise reduction features and optimized power consumption profile.

Project Results

- 65% reduction in operational noise

- 45% improvement in battery life

- 20% size reduction while maintaining torque

- Zero field failures in 18 months of operation

- Client satisfaction leading to 3x larger follow-up order