Essential Components in Automated Fluid Control

Valve and meter systems form the backbone of automated fluid control across industries, from water treatment facilities to chemical processing plants. These critical components require precise, reliable motor-driven mechanisms to ensure optimal performance.

- Core Functions: Valves and meters serve as the central hub for flow regulation and measurement in automated systems

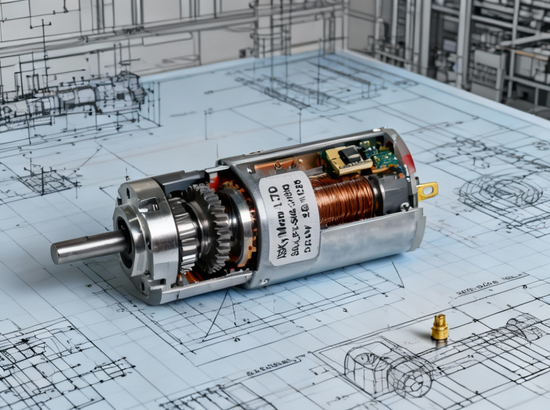

- Motor Integration: Electric motors drive valve positioning, meter calibration, and measurement module operations

- Control Precision: Motor-driven systems enable precise angle control for valve opening/closing and accurate pointer positioning in measurement instruments

- System Reliability: Consistent motor performance ensures uninterrupted flow control and accurate measurement data